Introduction

Lead has been a critical part of industries for centuries, from batteries to shielding materials. However, lead is also highly toxic in large amounts, making recycling efforts crucial. In this blog post, we will explore lead scrap, its applications, and the importance of converting lead scrap into ingots for reuse in the industry.

Why Lead is a Valuable Metal

Lead is known for its dense, malleable, and corrosion-resistant properties, making it ideal for several applications, such as:

Batteries

Lead is primarily used in lead-acid batteries, which power everything from cars to backup systems.

Radiation Shielding

Due to its high density, lead is used in medical and nuclear industries to block harmful radiation.

Ammunition

Lead is used in bullets and shot, as it is soft and heavy, providing the necessary mass for projectiles.

Construction and Plumbing

Lead is used in piping, roofing, and soundproofing materials

With these applications, lead is integral to several industries, but due to its toxicity, recycling is a necessity.

Lead Scrap: What It Is and Why It Matters

Lead scrap refers to any discarded or leftover lead material, including:

Used Batteries

Old lead-acid batteries, which are the most common source of lead scrap.

Lead-based Products

Old pipes, cables, and roofing materials that have been replaced.

Industrial Waste

Waste generated during the manufacturing of lead products.

Recycling lead scrap is essential for several reasons, including preventing environmental contamination and conserving valuable resources.

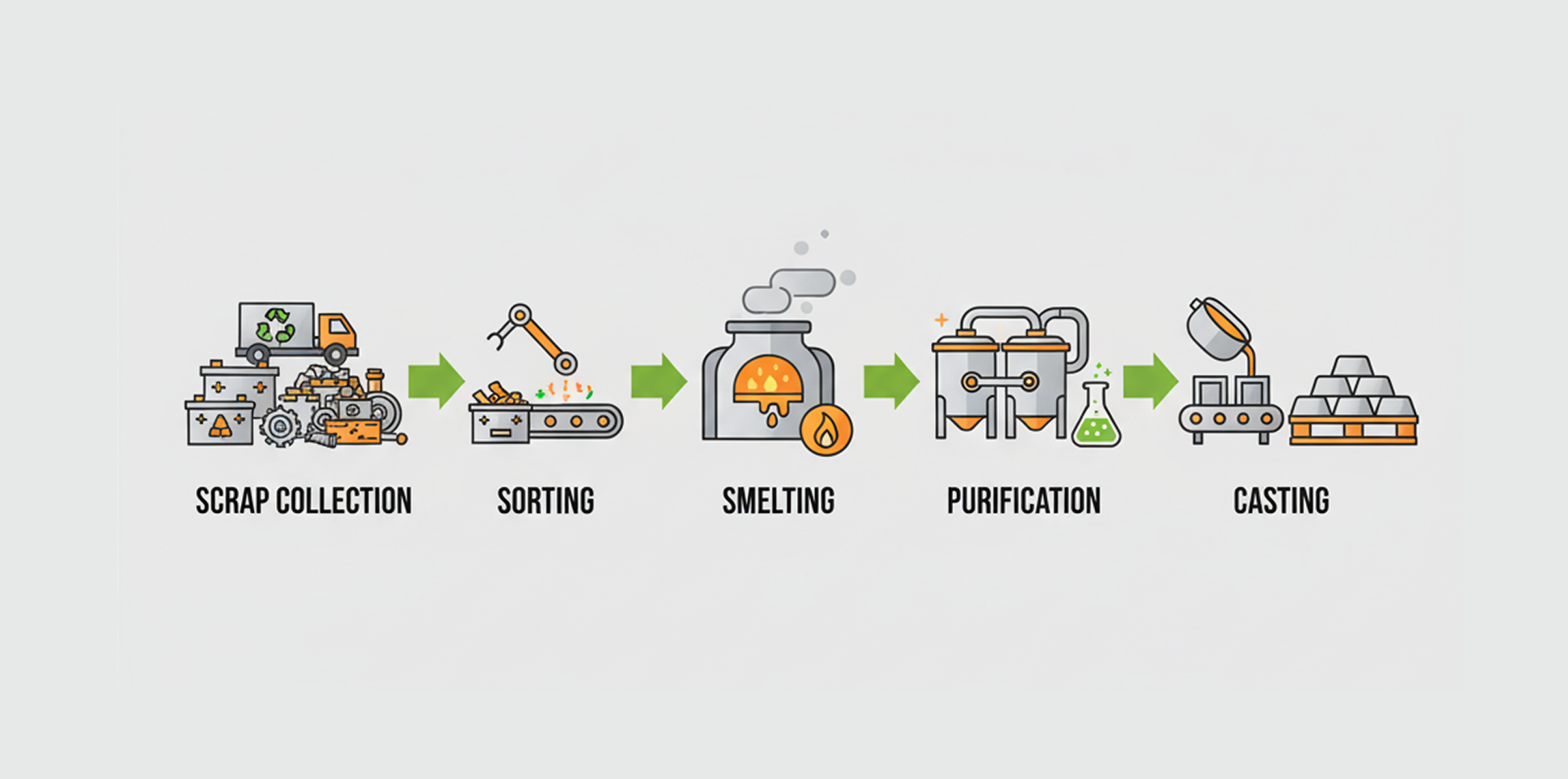

The Lead Recycling Process

Recycling lead scrap involves a well-defined process to ensure the safe handling and conversion of lead into ingots:

Collection and Sorting:

Lead scrap is gathered from various sources and sorted based on its form (e.g., lead-acid batteries, pipes, etc.).

Discharge of Batteries

For lead-acid batteries, the first step is discharging the batteries to avoid any hazardous reactions.

Shredding and Cleaning

The lead scrap is shredded to increase surface area for easier processing. Any impurities are removed in this phase.

Melting and Purification

The shredded scrap is then melted at high temperatures in a furnace. Impurities such as sulfur and other metals are removed through refining processes, ensuring the lead is of high purity.

Casting into Ingots

Once purified, the molten lead is poured into molds and allowed to solidify into lead ingots.

Packaging and Distribution

After cooling, the lead ingots are carefully packaged and sent to industries for reuse, such as battery manufacturing or construction.

Environmental and Economic Benefits of Lead Recycling

Environmental and Economic Benefits of Lead Recycling

Environmental Protection

Recycling reduces the need for new lead mining, which can be harmful to the environment. By processing lead scrap, we keep dangerous materials out of landfills and prevent lead contamination of soil and water.

Economic Value

Recycled lead is less expensive to produce than extracting new lead, making it a cost-effective material for manufacturers.

Sustainability

Lead is a finite resource. Recycling helps ensure that lead remains available for future use while reducing the need for harmful mining activities.

Our Role in Lead Scrap Processing

Our company is committed to ensuring that lead scrap is processed in a safe, environmentally responsible manner. By converting lead scrap into high-quality lead ingots, we help businesses in battery manufacturing, construction, and other industries access a reliable, sustainable supply of lead.

Conclusion

Recycling lead is an essential part of reducing environmental impact and conserving resources. As a company dedicated to scrap processing and ingot production, we play a vital role in ensuring that lead can be reused safely and effectively, helping industries continue to use this valuable metal while protecting the environment for future generations.

2 Comments

WealCoder

November 4, 20244:02 am

Over the past three years, marketers have faced an arduous journey due to the rapid shifts in consumer sentiment and the rising costs associated….

WealCoder

December 29, 20248:04 am

hello