Introduction

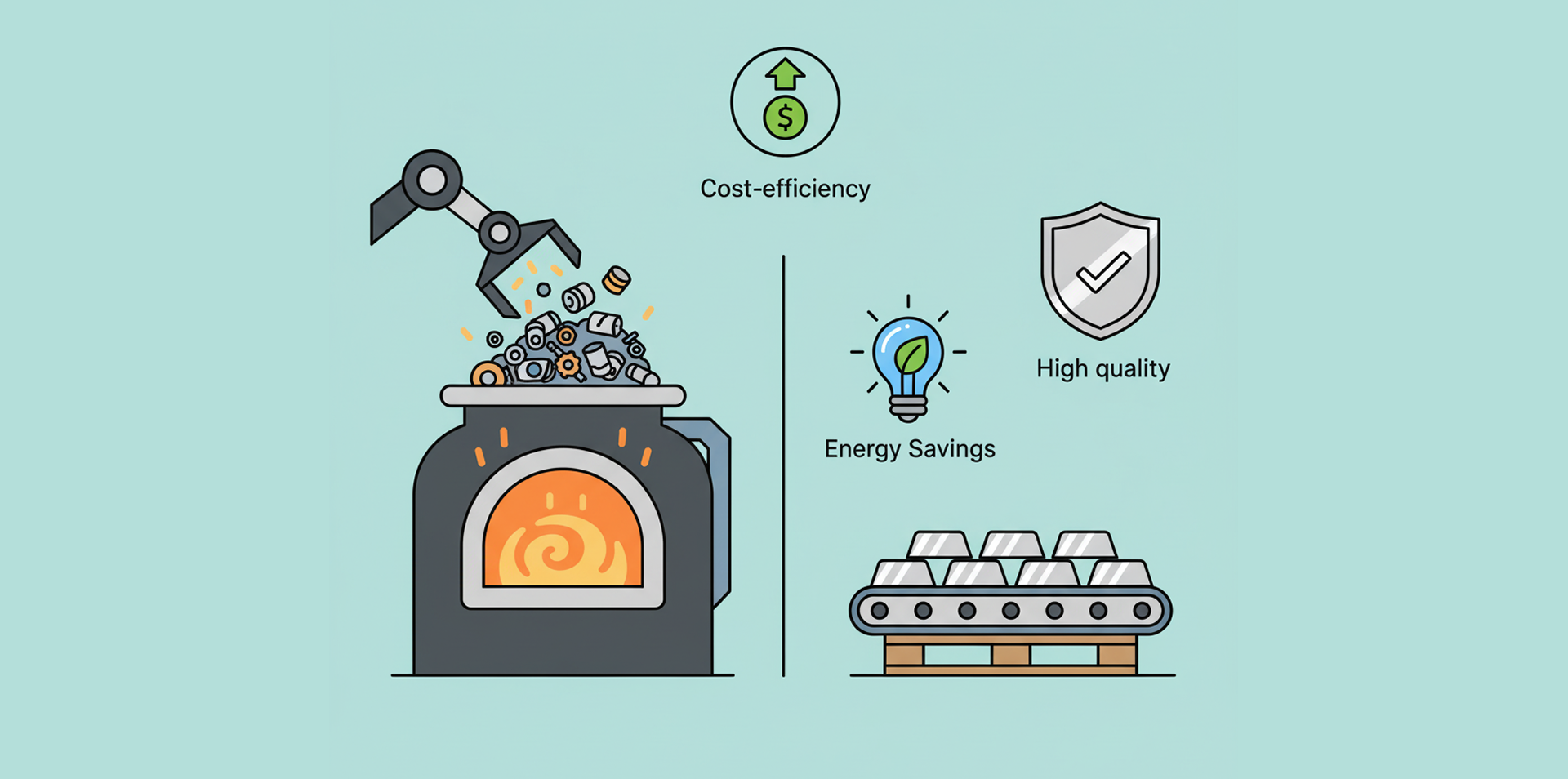

Aluminum recycling is a complex process that begins with melting scrap metal in specialized furnaces. The efficiency and cost-effectiveness of the process are heavily influenced by the type of furnace used. In this guide, we’ll explore the various furnace technologies used in aluminum recycling, their advantages, and how each type contributes to producing high-quality aluminum ingots.

Types of Furnaces Used in Aluminum Recycling

Lead is known for its dense, malleable, and corrosion-resistant properties, making it ideal for several applications, such as:

Induction Furnaces

Induction furnaces are considered one of the most energy-efficient technologies for aluminum recycling. These furnaces work by using an electromagnetic field to induce heat within the metal. The furnace itself does not come in direct contact with the metal, which reduces wear and tear and allows for faster melting.

Advantages:- o Low energy consumption

- o Rapid and uniform heating

- o Less oxidation, preserving metal purity

Best For: Small to medium-scale operations, where high-quality metal is required

Rotary Furnaces

Rotary furnaces are ideal for handling mixed scrap, such as aluminum contaminated with plastics or other non-metallic materials. These furnaces consist of a rotating drum that ensures uniform heating of the scrap.

Advantages:- o Effective for processing mixed or contaminated scrap

- o Excellent for heavy-duty applications

- o Uniform melt quality

Best For: Large-scale aluminum foundries or plants dealing with industrial scrap.

Reverberatory Furnaces

Reverberatory furnaces are commonly used for large-scale aluminum melting operations. The design of these furnaces involves a large, flat chamber where heat is reflected off the roof and walls to melt the aluminum.

Advantages:- o High capacity for bulk processing

- o Excellent for producing large quantities of ingots

- o Can handle both scrap and dross

Best For: Large production facilities where high-volume melting is required.

High-Frequency Furnaces

These furnaces use high-frequency electrical currents to heat the aluminum, allowing for precise temperature control. The ability to closely monitor temperature is critical for high-quality ingot production.

Advantages:- o Precise temperature control

- o Ideal for high-end, high-purity aluminum products

- o Faster melting times

Best For: High-precision, high-quality applications such as aerospace or electronics manufacturing.

Energy Efficiency in Furnace Technologies

In today’s competitive market, energy costs are a significant concern for aluminum recycling facilities. Induction furnaces, for example, are highly energy-efficient because they minimize heat loss compared to other furnace types. The energy-saving capabilities of modern furnaces have been further enhanced by the use of regenerative burners, heat recovery systems, and automation technologies.

Regenerative Burners

These burners capture waste heat from exhaust gases and use it to pre-heat incoming combustion air. This reduces the overall fuel consumption of the furnace.

Heat Recovery Systems

By incorporating heat recovery systems into the melting process, facilities can reuse the waste heat generated during aluminum processing, reducing the need for external energy sources.

Automated Systems

Automation in furnace operation helps to optimize the melting process, reducing human error and improving overall furnace efficiency.

Choosing the Right Furnace for Your Facility

The choice of furnace technology depends on various factors such as:

The volume of aluminum scrap being processed

The type of scrap (clean vs. contaminated)

The desired purity of the final product

Energy consumption goals

Manufacturers must balance furnace cost, energy efficiency, and production capacity when making this decision.

Conclusion

The choice of furnace plays a crucial role in the efficiency and cost-effectiveness of aluminum recycling. Understanding the specific needs of your production facility will help you choose the right technology to optimize both operational costs and environmental impact. With advancements in furnace technologies, there are now more options than ever to improve the aluminum recycling process.

2 Comments

WealCoder

November 4, 20244:02 am

Over the past three years, marketers have faced an arduous journey due to the rapid shifts in consumer sentiment and the rising costs associated….

WealCoder

December 29, 20248:04 am

hello